Formulating Surfactant Chemicals for the Rokan Block

Jakarta – The majority of oil fields in Indonesia are mature assets that have been in production since the early years of the nation’s independence. Among the most prominent is the Rokan Working Area (WK Rokan), particularly the Minas Field, which has consistently produced oil since 1952 and has long supported the national energy supply. With an estimated original oil reserves around 8.7 billion barrels, this giant field has been recorded as one of the main pillars of Indonesia's energy security and a major driver of economic activity for more than seven decades.

To sustain production levels, a range of technologies has been implemented and continuously refined at the Minas Field in Riau Province. Development began with peripheral water injection during the early stages of field exploitation, followed by the implementation of waterflooding in 1995. Since then, innovation has remained a constant priority.

Various tertiary recovery technologies have also been tested, including the application of Chemical Enhanced Oil Recovery (CEOR) through chemical injection. This innovation was initiated under the previous operator through a series of field trials.

Following the transfer of operatorship of the Rokan Working Area to Pertamina through its subsidiary, PT Pertamina Hulu Rokan (PHR), efforts to further develop Chemical Enhanced Oil Recovery (CEOR) have been significantly intensified. Pertamina has mobilized its best talents through close collaboration between the WK Rokan team, Pertamina’s Technology Innovation and Implementation (TI&I) function, and supporting subsidiaries to identify an optimal CEOR formulation and manufacture it domestically. This initiative is expected to reduce dependence on pre-transition chemical suppliers while strengthening Indonesia’s national energy self-reliance.

The development of the surfactant formulation has been a long and meticulous journey. It required sustained commitment, perseverance, and rigorous precision before the research outcomes were deemed ready for field application. Over nearly two years, Pertamina’s laboratory research team tested hundreds of chemical samples to identify a formulation capable of performing optimally under the specific reservoir characteristics of the Rokan Working Area.

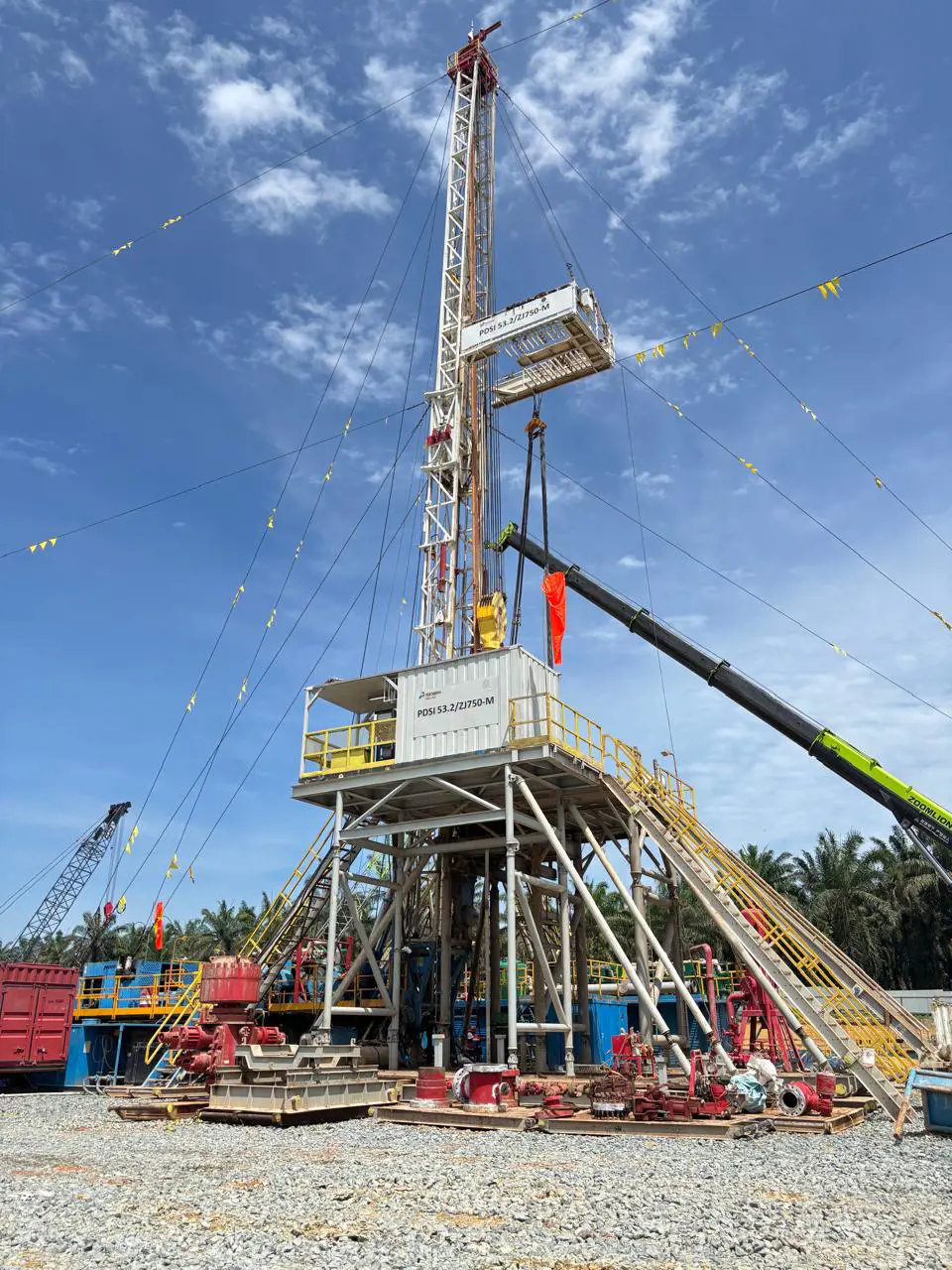

Following a field trial in July 2025 through the Surfactant Extended Stimulation (SES) Project at the Balam South Field in Rokan Hilir Regency on Tuesday, 23 December 2025, marked a significant milestone for PT Pertamina Hulu Rokan (PHR). On that day, the Chemical Enhanced Oil Recovery (CEOR) project was officially launched at Minas Field Area A, Rokan Zone. The inauguration ceremony held in Rumbai reaffirmed PHR’s commitment to optimizing hydrocarbon production in support of national energy security.

Head of the Special Task Force for Upstream Oil and Gas Business Activities (SKK Migas), Djoko Siswanto, emphasized that the Minas Field is one of the most important assets in the history of Indonesia’s upstream oil and gas industry, having made a substantial contribution to meeting national energy demand over several decades.

“However, we also recognize that Minas is a mature field. Sustaining its production can only be achieved through innovation and the application of appropriate technology. Therefore, we are grateful to officially inaugurate the implementation of Phase I Chemical EOR in Area A of the Minas Field today,” said Djoko.

Meanwhile, Vice President Director of PT Pertamina (Persero), Oki Muraza, stated that the success of CEOR, particularly in mature fields, demonstrates how technological innovation can extend field life, improve recovery factors, and strengthen national energy resilience.

“What we can truly take pride in is that the surfactant, as the core component of this CEOR technology, is the result of innovation by Pertamina’s own professionals. Its effectiveness has been validated through a series of laboratory and field tests, ensuring the reliability and readiness of this technology for commercial deployment,” Oki remarked.

The primary surfactant used in the project was specifically formulated to perform optimally across Pertamina-operated fields. Its development involved close synergy with several subsidiaries, including PT Pertamina Lubricants (PTPL) and Elnusa Petrofin, covering the entire value chain—from raw material procurement, blending processes, quality assurance and quality control (QA/QC), to distribution at project sites. All stages have successfully passed comprehensive laboratory and field testing.

“In addition to internal research, we also received parallel support from various stakeholders, including third-party technology providers, academics, and experts from both domestic and international backgrounds,” said Agus Masduki, Manager of EOR Petroleum Engineering, PHR Regional 1 – Sumatra.

Hundreds of Samples, Hundreds of Trials, and Time Pressure

One of the greatest challenges in the search for an effective surfactant was identifying a formulation that delivers optimal performance while remaining cost-effective. Unlike off-the-shelf products available in the global market, which only require compatibility verification, this initiative demanded hundreds of formulation trials to meet highly specific technical criteria.

“The most difficult part was finding the main surfactant component itself,” Agus explained.

The search process spanned nearly two years and involved more than 80 laboratory test cycles. Of the dozens of formulations evaluated, only a small fraction demonstrated performance approaching the predefined technical requirements.

Senior Laboratory Analyst at PHR, Ester Tio Minar E. Silalahi, played a pivotal role in this effort. With extensive experience in surfactant formulation, Ester led intensive laboratory testing and analysis. Together with a nine-member team, she worked relentlessly to identify the most suitable formulation.

“We received hundreds of surfactant samples, and the biggest challenge was identifying the right and most optimal combination,” Ester said.

According to her, not all surfactants can perform stably under the chemical conditions and reservoir characteristics of the Rokan fields. As a result, the team adopted a detailed scientific approach—ranging from in-depth literature reviews and regular discussions to repeated testing of various material combinations.

“Meetings were held almost daily. Hundreds of tests were conducted, and the results were continuously reviewed. Whenever challenges arose, we immediately discussed them intensively,” she added.

Beyond the laboratory, parallel efforts were also underway. In addition to internal formulation development involving laboratory teams, EOR specialists, and cross-functional units at Pertamina (Persero), the team actively explored chemical manufacturers both domestically and internationally—including producers with no prior collaboration history.

Through perseverance, collaboration, and a consistent scientific approach, PHR’s laboratory team has demonstrated that innovation in the upstream oil and gas sector is not solely about technology, but also about the resilience and dedication of the people behind it.

ABOUT PHR ROKAN ZONE

PT Pertamina Hulu Rokan (PHR) is a subsidiary of Pertamina operating in the upstream oil and gas sector under the Upstream Subholding, PT Pertamina Hulu Energi (PHE). PHR was established on 20 December 2018.

Pertamina was mandated by the Government of Indonesia to manage the Rokan Working Area starting 9 August 2021 and subsequently appointed PHR to undertake the operatorship transition from the previous operator. The transition process was executed safely, smoothly, and reliably. PHR will continue to operate the Rokan Working Area for a 20-year period, from 9 August 2021 until 8 August 2041.

The Rokan Working Area covers approximately 6,200 square kilometers across seven regencies and cities in Riau Province. It comprises 80 active fields, approximately 11,300 wells, and 35 gathering stations. WK Rokan contributes roughly one-quarter of Indonesia’s crude oil production, or about one-third of Pertamina’s total output. In addition to producing oil and gas for the nation, PHR also manages social and environmental responsibility programs with a focus on education, health, community economic empowerment, and environmental sustainability.With an estimated original oil reserves around 8.7 billion barrels, this giant field has been recorded as one of the main pillars of Indonesia's energy security and a major driver of economic activity for more than seven decades.

To sustain production levels, a range of technologies has been implemented and continuously refined at the Minas Field in Riau Province. Development began with peripheral water injection during the early stages of field exploitation, followed by the implementation of waterflooding in 1995. Since then, innovation has remained a constant priority.

Various tertiary recovery technologies have also been tested, including the application of Chemical Enhanced Oil Recovery (CEOR) through chemical injection. This innovation was initiated under the previous operator through a series of field trials.

Following the transfer of operatorship of the Rokan Working Area to Pertamina through its subsidiary, PT Pertamina Hulu Rokan (PHR), efforts to further develop Chemical Enhanced Oil Recovery (CEOR) have been significantly intensified. Pertamina has mobilized its best talents through close collaboration between the WK Rokan team, Pertamina’s Technology Innovation and Implementation (TI&I) function, and supporting subsidiaries to identify an optimal CEOR formulation and manufacture it domestically. This initiative is expected to reduce dependence on pre-transition chemical suppliers while strengthening Indonesia’s national energy self-reliance.

The development of the surfactant formulation has been a long and meticulous journey. It required sustained commitment, perseverance, and rigorous precision before the research outcomes were deemed ready for field application. Over nearly two years, Pertamina’s laboratory research team tested hundreds of chemical samples to identify a formulation capable of performing optimally under the specific reservoir characteristics of the Rokan Working Area.

Following a field trial in July 2025 through the Surfactant Extended Stimulation (SES) Project at the Balam South Field in Rokan Hilir Regency on Tuesday, 23 December 2025, marked a significant milestone for PT Pertamina Hulu Rokan (PHR). On that day, the Chemical Enhanced Oil Recovery (CEOR) project was officially launched at Minas Field Area A, Rokan Zone. The inauguration ceremony held in Rumbai reaffirmed PHR’s commitment to optimizing hydrocarbon production in support of national energy security.

Head of the Special Task Force for Upstream Oil and Gas Business Activities (SKK Migas), Djoko Siswanto, emphasized that the Minas Field is one of the most important assets in the history of Indonesia’s upstream oil and gas industry, having made a substantial contribution to meeting national energy demand over several decades.

“However, we also recognize that Minas is a mature field. Sustaining its production can only be achieved through innovation and the application of appropriate technology. Therefore, we are grateful to officially inaugurate the implementation of Phase I Chemical EOR in Area A of the Minas Field today,” said Djoko.

Meanwhile, Vice President Director of PT Pertamina (Persero), Oki Muraza, stated that the success of CEOR, particularly in mature fields, demonstrates how technological innovation can extend field life, improve recovery factors, and strengthen national energy resilience.

“What we can truly take pride in is that the surfactant, as the core component of this CEOR technology, is the result of innovation by Pertamina’s own professionals. Its effectiveness has been validated through a series of laboratory and field tests, ensuring the reliability and readiness of this technology for commercial deployment,” Oki remarked.

The primary surfactant used in the project was specifically formulated to perform optimally across Pertamina-operated fields. Its development involved close synergy with several subsidiaries, including PT Pertamina Lubricants (PTPL) and Elnusa Petrofin, covering the entire value chain—from raw material procurement, blending processes, quality assurance and quality control (QA/QC), to distribution at project sites. All stages have successfully passed comprehensive laboratory and field testing.

“In addition to internal research, we also received parallel support from various stakeholders, including third-party technology providers, academics, and experts from both domestic and international backgrounds,” said Agus Masduki, Manager of EOR Petroleum Engineering, PHR Regional 1 – Sumatra.

Hundreds of Samples, Hundreds of Trials, and Time Pressure

One of the greatest challenges in the search for an effective surfactant was identifying a formulation that delivers optimal performance while remaining cost-effective. Unlike off-the-shelf products available in the global market, which only require compatibility verification, this initiative demanded hundreds of formulation trials to meet highly specific technical criteria.

“The most difficult part was finding the main surfactant component itself,” Agus explained.

The search process spanned nearly two years and involved more than 80 laboratory test cycles. Of the dozens of formulations evaluated, only a small fraction demonstrated performance approaching the predefined technical requirements.

Senior Laboratory Analyst at PHR, Ester Tio Minar E. Silalahi, played a pivotal role in this effort. With extensive experience in surfactant formulation, Ester led intensive laboratory testing and analysis. Together with a nine-member team, she worked relentlessly to identify the most suitable formulation.

“We received hundreds of surfactant samples, and the biggest challenge was identifying the right and most optimal combination,” Ester said.

According to her, not all surfactants can perform stably under the chemical conditions and reservoir characteristics of the Rokan fields. As a result, the team adopted a detailed scientific approach—ranging from in-depth literature reviews and regular discussions to repeated testing of various material combinations.

“Meetings were held almost daily. Hundreds of tests were conducted, and the results were continuously reviewed. Whenever challenges arose, we immediately discussed them intensively,” she added.

Beyond the laboratory, parallel efforts were also underway. In addition to internal formulation development involving laboratory teams, EOR specialists, and cross-functional units at Pertamina (Persero), the team actively explored chemical manufacturers both domestically and internationally—including producers with no prior collaboration history.

Through perseverance, collaboration, and a consistent scientific approach, PHR’s laboratory team has demonstrated that innovation in the upstream oil and gas sector is not solely about technology, but also about the resilience and dedication of the people behind it.

ABOUT PHR ROKAN ZONE

PT Pertamina Hulu Rokan (PHR) is a subsidiary of Pertamina operating in the upstream oil and gas sector under the Upstream Subholding, PT Pertamina Hulu Energi (PHE). PHR was established on 20 December 2018.

Pertamina was mandated by the Government of Indonesia to manage the Rokan Working Area starting 9 August 2021 and subsequently appointed PHR to undertake the operatorship transition from the previous operator. The transition process was executed safely, smoothly, and reliably. PHR will continue to operate the Rokan Working Area for a 20-year period, from 9 August 2021 until 8 August 2041.

The Rokan Working Area covers approximately 6,200 square kilometers across seven regencies and cities in Riau Province. It comprises 80 active fields, approximately 11,300 wells, and 35 gathering stations. WK Rokan contributes roughly one-quarter of Indonesia’s crude oil production, or about one-third of Pertamina’s total output. In addition to producing oil and gas for the nation, PHR also manages social and environmental responsibility programs with a focus on education, health, community economic empowerment, and environmental sustainability.